The fashion industry is always a full season ahead of the rest of the world. This is shown through the biggest fashion trade show in the world, Magic/Pool/Project trade shows in Las Vegas, they happen twice a year (Feb and Aug) and each trade show is for the season that they are currently in but ONE YEAR ahead (Feb is the fall show, Aug is the spring show). This system requires independent brands to keep up with this by coming out very early with their lines to impress buyers.

As screen printers, because of this, we are usually printing tank tops in the dead winter, and long sleeved hoodies in the heat of summer. Some people who see this wonder "Who could possibly be ordering something so late", but this is due to the trends that are in place.

We recently printed some tank tops for a really rad Canadian brand, RBLTG, out of Regina Beach, Saskatchewan. Single color samples on white and black. We also individually folded and bagged each one before shipping to them. Keep up the good work, boys!!

February 24, 2014

February 10, 2014

Custom Printed Designer Tags

Sometimes even the most simple things take a lot of time and effort to perfect. Our friend, Shaina Mote, Women's fashion designer, extraordinaire, needed to re-up on her stockpile of printed custom tags for her new lines that she is sampling right now, and we were her go-to to get those done.

These tags were just strips of fabric, almost like edging or trim, but natural canvas style edging. She cuts it into strips and we print her custom tags right over top of them, then she is able to cut them and sew them directly into the garments when she produces her new lines. Its a really cheap and professional way for Shaina to get really nice custom tags made, and the way that we have developed printing them, its easy for us to churn out lots of these tags with minimal effort.

There are SO many ways to develop cheap and easy workarounds in the fashion world by using Screen printing as the medium, a way to avoid high minimums by other industries yet still keeping the quality as the highest priority!

These tags were just strips of fabric, almost like edging or trim, but natural canvas style edging. She cuts it into strips and we print her custom tags right over top of them, then she is able to cut them and sew them directly into the garments when she produces her new lines. Its a really cheap and professional way for Shaina to get really nice custom tags made, and the way that we have developed printing them, its easy for us to churn out lots of these tags with minimal effort.

There are SO many ways to develop cheap and easy workarounds in the fashion world by using Screen printing as the medium, a way to avoid high minimums by other industries yet still keeping the quality as the highest priority!

February 5, 2014

Large Format Fabric Printing for Superbowl 2014

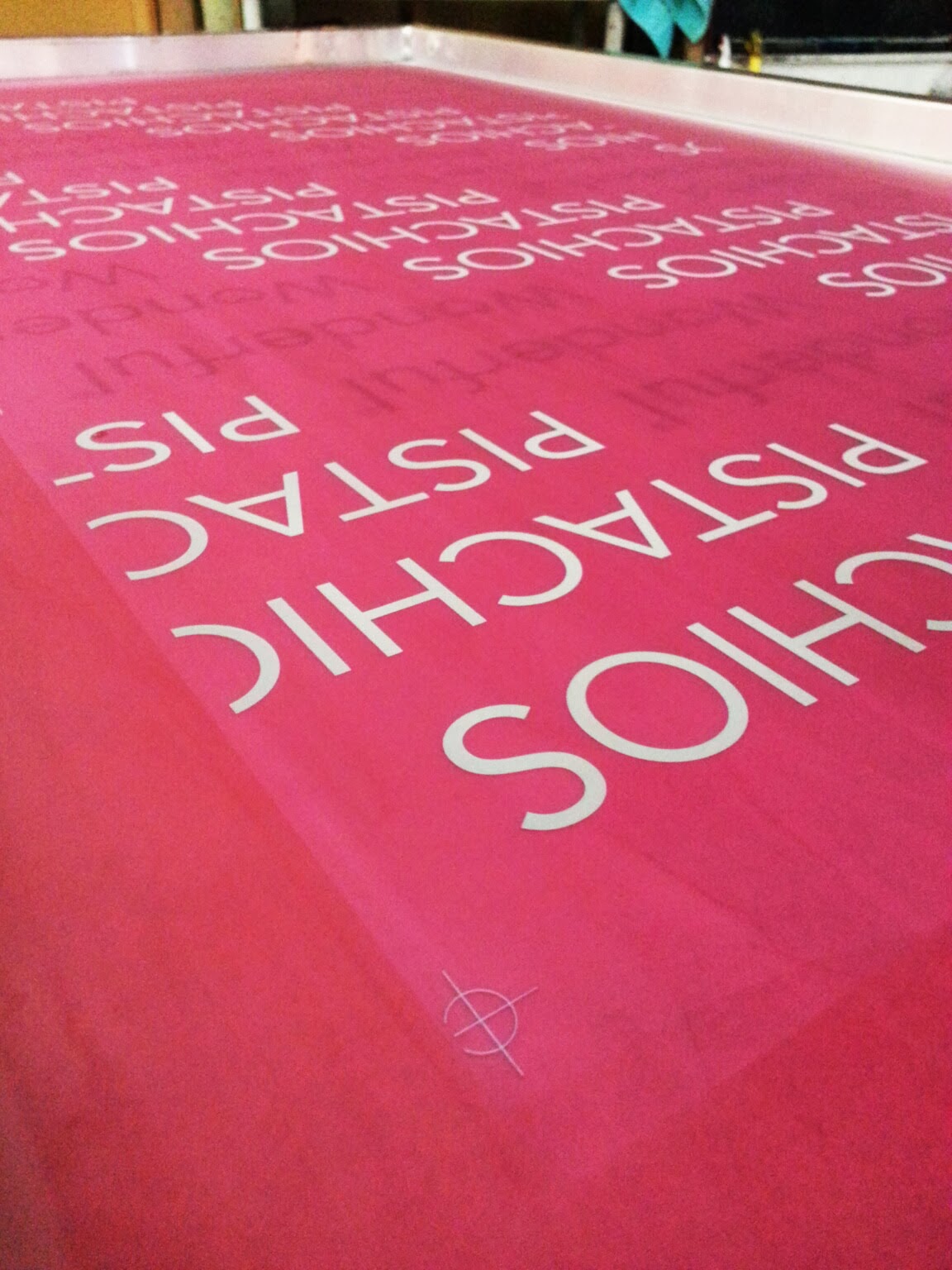

Superbowl time has come: and so has the time for the amazing commercials that are made just for that one single game. We had the chance to print some fabric for the Pistachio Wonderful Superbowl commercial (as seen HERE). Our main man Stephen Colbert is staring in the commercial, with his eagle costar, wearing a custom made suit that we printed.

We were given the feat to print multicolored prints on a large roll of fabric. Although this was superbly impossible for most printers to take on, we feel differently about custom jobs as this one, and we took this job on, ready to rock it!

STEP 1: Prepping - Doing this wasn't easy, as we weren't set up for it and really had to improvise with our materials and process of getting this done. First step: Getting a pallet (table) to attach to the press in order to print on, and fit the screens on. This was done by us cutting down some piece of wall in our shop in order to get a smooth surface to attach to a piece of wood.

STEP 2: Setting up the screens - This was a tedious step, as the screens are VERY large custom made screens and having them fit onto the press was difficult enough, let alone registering them together AND making sure nothing moves during production.

STEP 3: Printing - Whenever anything this large is being printed, there are always difficulties with the print either looking too LIGHT, or there being lines in it from where the squeege passed thru the image (depending on the size of squegee there is). Luckily with this print, we were able to use a small squeegee and go over each individual word to make it look thick but without lines. After this, flash drying it in between colors took a while with our small little flash, then printing the 2nd color was stressful, but overall we really got a handle on the printing of this and really busted it out.

STEP 4: Finishing - properly curing the fabric AND finishing it up with the presentation was key for us. It doesn't come everyday where you get to print for a multi-million dollar Superbowl commerical, and we wanted to really impress the clients here.

Its jobs like this that we REALLY love to take on, say YES to when most shops say NO (since they dont want to waste their time doing anything outside of the norm), but we LOVE doing custom jobs like this, cause not only are we able to venture outside our "screen printer" selves and really touch the inner "Artist" that we are to help create something like this, but we also learn SO much and thus, become much better printers because of it! (Next time someone asks us to print multi-color large format printing on fabric, we can say YES with confidence! :)

We were given the feat to print multicolored prints on a large roll of fabric. Although this was superbly impossible for most printers to take on, we feel differently about custom jobs as this one, and we took this job on, ready to rock it!

STEP 1: Prepping - Doing this wasn't easy, as we weren't set up for it and really had to improvise with our materials and process of getting this done. First step: Getting a pallet (table) to attach to the press in order to print on, and fit the screens on. This was done by us cutting down some piece of wall in our shop in order to get a smooth surface to attach to a piece of wood.

STEP 2: Setting up the screens - This was a tedious step, as the screens are VERY large custom made screens and having them fit onto the press was difficult enough, let alone registering them together AND making sure nothing moves during production.

STEP 3: Printing - Whenever anything this large is being printed, there are always difficulties with the print either looking too LIGHT, or there being lines in it from where the squeege passed thru the image (depending on the size of squegee there is). Luckily with this print, we were able to use a small squeegee and go over each individual word to make it look thick but without lines. After this, flash drying it in between colors took a while with our small little flash, then printing the 2nd color was stressful, but overall we really got a handle on the printing of this and really busted it out.

STEP 4: Finishing - properly curing the fabric AND finishing it up with the presentation was key for us. It doesn't come everyday where you get to print for a multi-million dollar Superbowl commerical, and we wanted to really impress the clients here.

Its jobs like this that we REALLY love to take on, say YES to when most shops say NO (since they dont want to waste their time doing anything outside of the norm), but we LOVE doing custom jobs like this, cause not only are we able to venture outside our "screen printer" selves and really touch the inner "Artist" that we are to help create something like this, but we also learn SO much and thus, become much better printers because of it! (Next time someone asks us to print multi-color large format printing on fabric, we can say YES with confidence! :)

Subscribe to:

Comments (Atom)