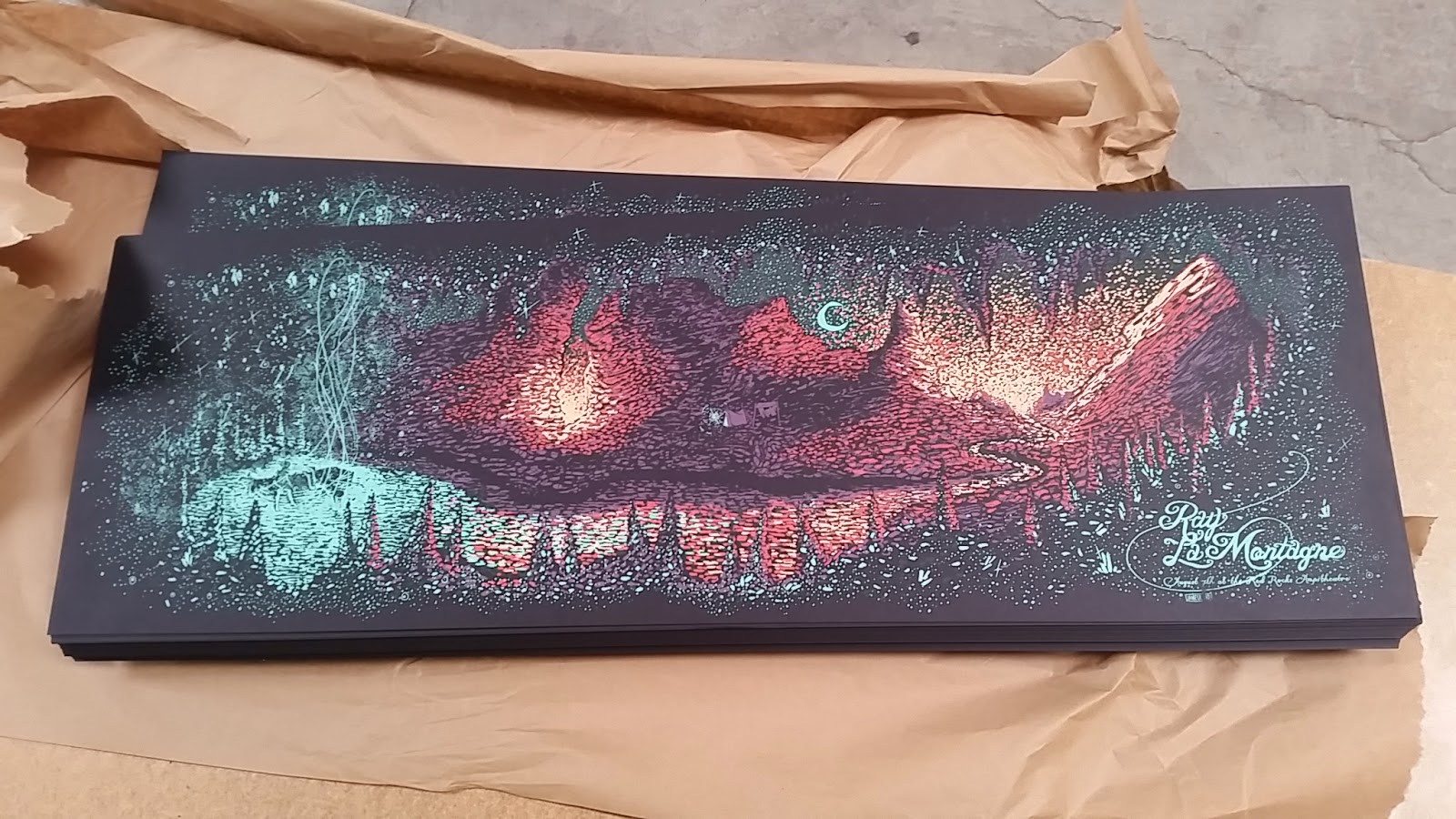

Hand Screen Printed posters are amazing. One of our favorite things in the shop is having the chance to print amazingly well designed tour posters. The difference between cheap full color offset printed posters and hand screen printed posters is obvious: one is cheaply made, bland and something that is machine made; and the other is beautifully crafted, hand made, ink that you can feel, and something that is as beautiful as it is unique. As screen printers, the ability to print flat stock is extremely more difficult than something like apparel...so for an artist-run shop like ours, we prefer printing things like posters because of the high caliber of experience it takes and the artistic value of the final product.

We had the ability to work with artist and illustrator James R. Eads to print some posters for Ray LaMontagne and his live show at the Red Rocks in Denver, Colorado. These posters were 5 colors and printed on French 110# coverstock, sized at 13" x 26". The pantone colors were selected by the artist, and we were able to do a run of about 200 of these. The posters turned out amazingly and we stand behind the idea that the print is ONLY as good as the artist: if you get a great artist and have the ability to print their artwork, the print will always look good due to the great illustration.

December 30, 2014

November 24, 2014

Tritonal Coroplast Custom Sign Printing

Complete Control Management hit us up for a very specialized project for one of

their DJ artists Tritonal, Corrugated plastic (Coroplast) printing with a

twist. Normally when we print on Coroplast, its fairly straight

forward. (square shaped signs, simple one color prints, usually ends up

hanging in the window or on the front lawn of a business.). These signs

were unique. Specially printed, customized shape, different colors, and a

very tight registration process to get them properly lined up before

cutting.

This

job prob took us half a day just to think about how to print and

register them properly. (mainly because we had to print them before

cutting mainly because of the full bleed of the signs. BUT if we printed

the front and backs off registration, when cut out they wouldn't line up).

Printing was done with a highly specialized Epoxy based Nazdar ink, made for plastics. Once printed, we cut a stencil out of wood of the final triangle design, to use as the template to cut out the full run of 100 pieces. This was done very delicately (given that this plastic cuts like butter), but were cut out from the outside AND inside pieces, leaving a doughnut-shaped triangle sign.We are pretty happy how these signs turned out, at the quality that the final product was. Now lets just hope that no one gets their eye poked out at a show by the corner of one of those things as it gets flung across the crowd! :)

November 17, 2014

Seeing Trails Bandana Printing

Hiking Group? Los Angeles? You wouldn't think those 2 things went together, seeing that there isn't many mountains in Los Angeles. Well the hiking group Seeing Trails has found a way to get around that. These guys make bi-weekly trips up to the San Gabriel Mountains to explore, hike, be together with friends and...well, See Trails! :)

They needed some bandanas. We created them. These bandanas not only got a pretty amazing and super unique dye wash (each one was pretty customized in and of itself) but we were also able to print their amazing logo large on the front of these bandanas.

Because these bandanas were going to be touching bare skin, we decided to use a very light waterbased ink made of charcoal. It is actually a very dark grey color and was best so there were no solvents or other harmful chemicals in any of the inks that we used here.

Great work guys! Keep up the amazing trip!

They needed some bandanas. We created them. These bandanas not only got a pretty amazing and super unique dye wash (each one was pretty customized in and of itself) but we were also able to print their amazing logo large on the front of these bandanas.

Because these bandanas were going to be touching bare skin, we decided to use a very light waterbased ink made of charcoal. It is actually a very dark grey color and was best so there were no solvents or other harmful chemicals in any of the inks that we used here.

Great work guys! Keep up the amazing trip!

November 13, 2014

Ommegang Umbrella Printing

One of the best parts of our job at Print Renegades is the ability we have to work with a vast mix of different projects and people. Most other print shops (in our eyes) basically do the same types of things everyday. Because we are always so open to taking on new and interesting projects, this gives us the ability to venture down a new and exciting road weekly (and what makes our print shop so unique).

Last week we had a chance to work with our old Belgian beer making friends, Ommegang. (we have printed for them before actually). They had a rush project that they needed help with, and we were able to assist them in making their dreams become a reality. They were doing a festival in Santa Monica and needed some umbrellas printing with their fancy logo on all 4 panels of each umbrella. This we had never done before, but we took it on and nailed it perfectly.

We used a specialized catalyst that we were able to mix into our standard ink to make it permanent on Nylon, and also makes it be able to endure outdoor weather on a more permanent basis. The print was a fairly simple one color design, and although measuring and making the print straight seemed to be the most complicated part of the job, they turned out pretty rad!

Bottoms up!!

Last week we had a chance to work with our old Belgian beer making friends, Ommegang. (we have printed for them before actually). They had a rush project that they needed help with, and we were able to assist them in making their dreams become a reality. They were doing a festival in Santa Monica and needed some umbrellas printing with their fancy logo on all 4 panels of each umbrella. This we had never done before, but we took it on and nailed it perfectly.

We used a specialized catalyst that we were able to mix into our standard ink to make it permanent on Nylon, and also makes it be able to endure outdoor weather on a more permanent basis. The print was a fairly simple one color design, and although measuring and making the print straight seemed to be the most complicated part of the job, they turned out pretty rad!

Bottoms up!!

October 6, 2014

Freshwata All Over Printing

Freshwata are tastemakers. Aside from their design and branding side of their business, they also focus on building and developing style for exhibits and social events. Freshwata were doing an event in San Diego and hit us up to help them with a very large and time consuming project: All Over Printing. This style of printing is usually done as a Dye Sublimiation process, but given that Freshwata wanted to have a few hundred of these done, it was cheaper and better for us to run these as standard discharge screen printing.

The shirts were standard Anvil 980 Fashion Fit tees. We then used a super large 160 mesh screen (roughly 58"x54" outside dimension) with Pro Discharge White discharge ink (mixed with the poly activator). This produced a bright white print while keeping the hand and feel of the ink very soft on the shirt AND making the print over the seams look much better than a standard plastisol ink would. (this is because the viscosity of this ink makes it easier to go over uneven areas, making them look less inconsistent and much cleaner than a heavier and thicker oil based ink would.)

Overall, printing AOP prints is extremely difficult, time consuming and costly but the overall final product is well worth all the work it takes to get the job finished. Even though we spend 16 straight hours on this job (and worked well into the morning on these), the result turned out well and we were very happy with the end result.

The shirts were standard Anvil 980 Fashion Fit tees. We then used a super large 160 mesh screen (roughly 58"x54" outside dimension) with Pro Discharge White discharge ink (mixed with the poly activator). This produced a bright white print while keeping the hand and feel of the ink very soft on the shirt AND making the print over the seams look much better than a standard plastisol ink would. (this is because the viscosity of this ink makes it easier to go over uneven areas, making them look less inconsistent and much cleaner than a heavier and thicker oil based ink would.)

Overall, printing AOP prints is extremely difficult, time consuming and costly but the overall final product is well worth all the work it takes to get the job finished. Even though we spend 16 straight hours on this job (and worked well into the morning on these), the result turned out well and we were very happy with the end result.

Subscribe to:

Comments (Atom)